Metal & Machine Shop Training Courses

Metal Shop Fundamentals

This training course introduces all of the traditional Metal Shop tools, including the: cold saw, horizontal bandsaw, vertical bandsaw, disc sander / grinder, drill press, sheet metal shear and sheet metal bending brake.

Successful completion of this training course will allow you to work independently on a wide variety of metal fabrication projects in the Metal Shop on all of the tool listed above.

Duration: 2 hours

Experience Level: Beginner

Pre-requisites: None

Price: $180

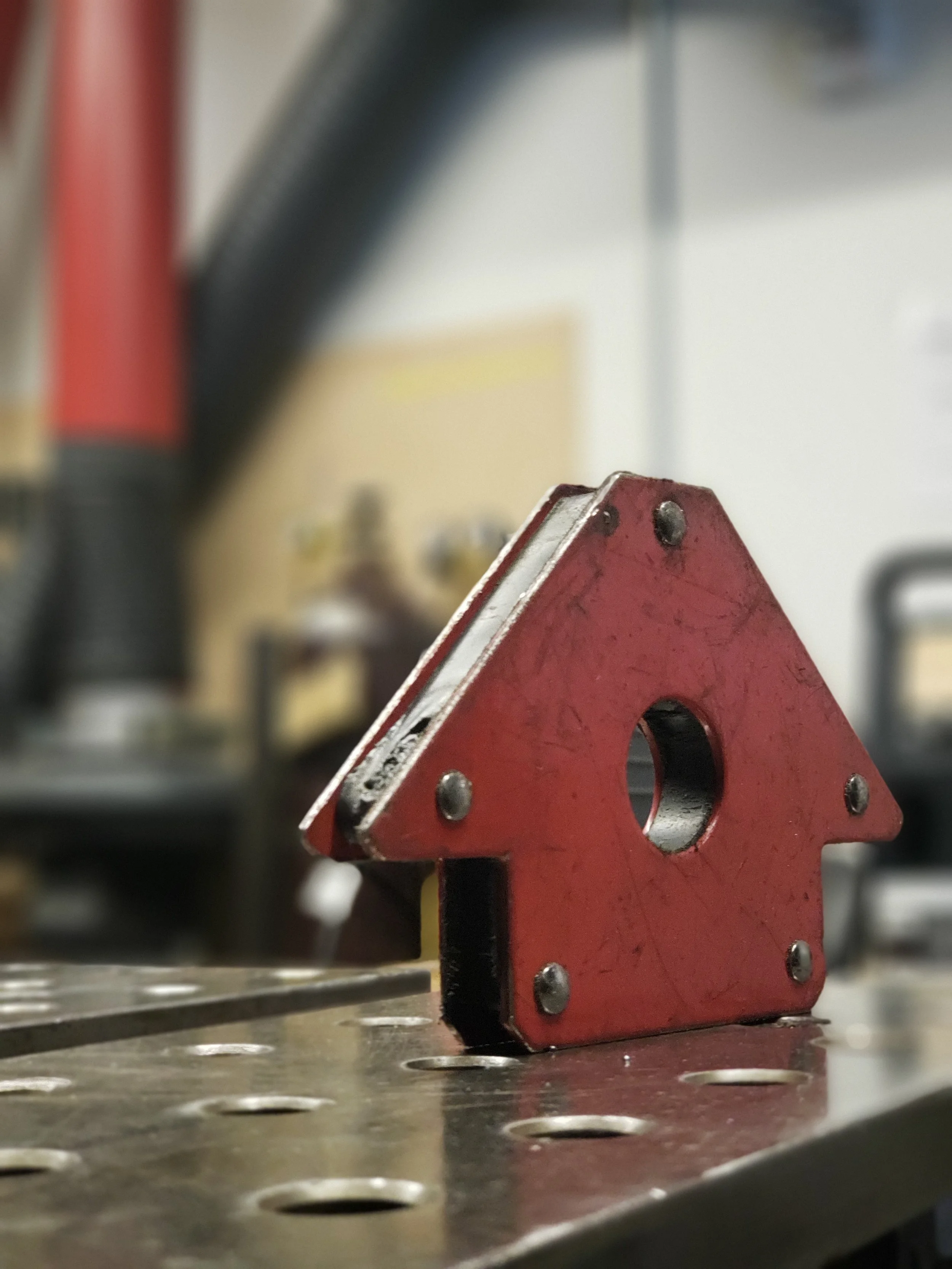

Welding

This comprehensive welding course introduces both MIG and TIG welding on our Miller Multimatic 220 welder. MIG welding (Metal Inert Gas) is a good starting point for new welders. The metal wire is automatically fed through a handheld welding gun, allowing for more point-and-shoot joining of metals. It produces a strong weld that may be rough or require grinding to be clean. TIG welding (Tungsten Inert Gas) is typically used for jobs that require a high level of control with a very clean end result. TIG offers welders more control over each step in the process by hand-feeding the filler material into the weld and allowing for variable power through a foot pedal. This is generally considered more advanced welding.

Successful completion of the training session will certify you on the combined MIG-TIG welding equipment.

Duration: 3 hours

Experience Level: Intermediate

Pre-requisites: Metal Shop Fundamentals is recommended

Price: $180

Manual Metal Lathe

This training introduces the manual metal lathe, an industrial machine shop tool that rotates a workpiece on axis, allowing you to cave and shape it using a variety of cutting tools, shaping tools, and drill bits. You can make custom handles, bushings, bearings, and other radially symmetrical machined components.

Successful completion of the training session will certify you on the Manual Metal Lathe.

Duration: 3.5 hours

Experience Level: Intermediate

Pre-requisites: Metal Shop Fundamentals is recommended

Price: $225

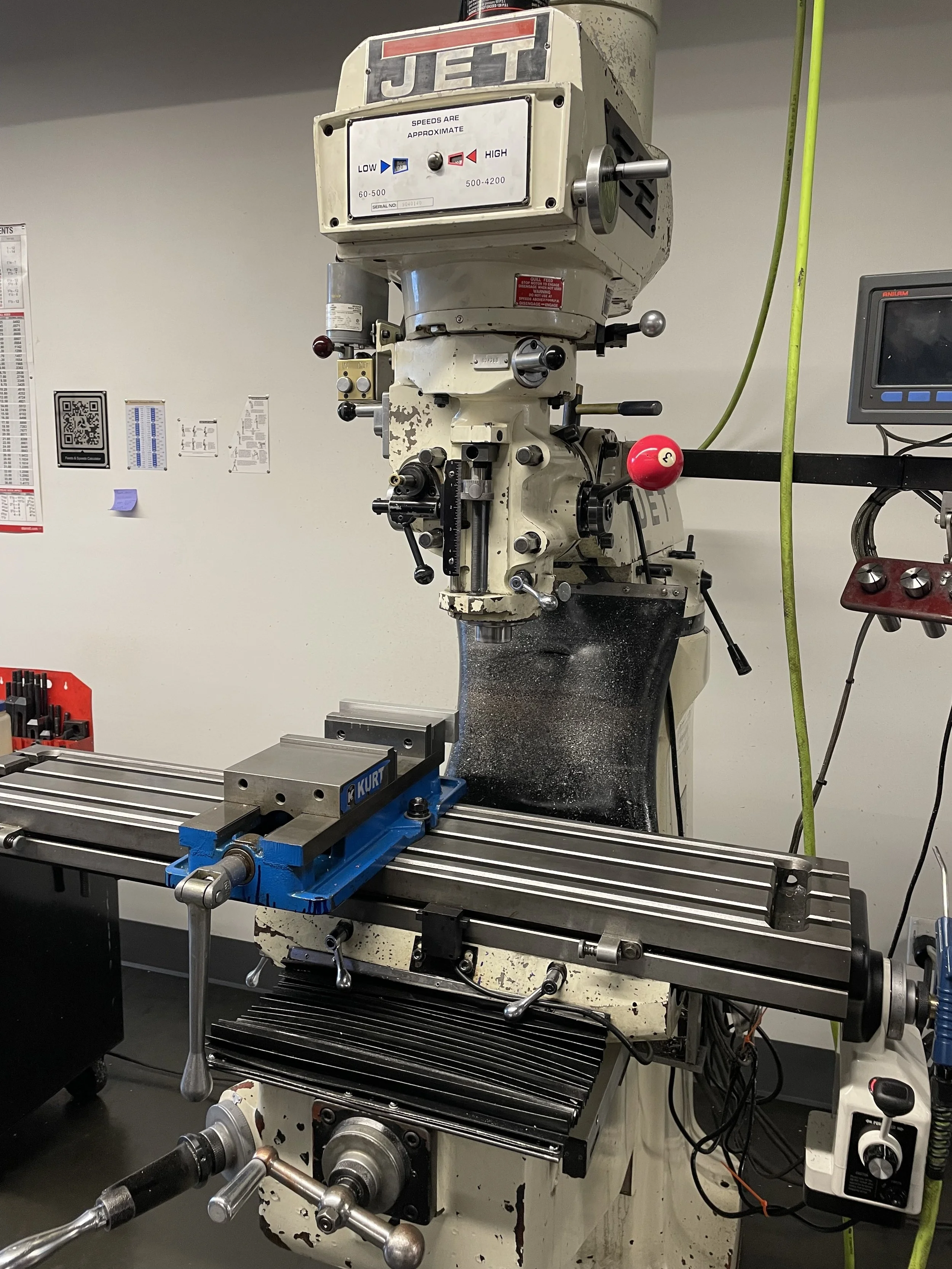

Manual Mill

This training course introduces the Manual Metal Mill, an industrial machine shop tool that functions by securely clamping a workpiece to a moving table, then using precise movements to guide the work past a rotating cutting tool. This allows you to accurately cut, shape, surface, drill, and bore metal workpieces.

Successful completion of the training session will certify you on the Manual Metal Mill.

Duration: 3 hours

Experience Level: Intermediate

Pre-requisites: Metal Shop Fundamentals is recommended

Price: $225

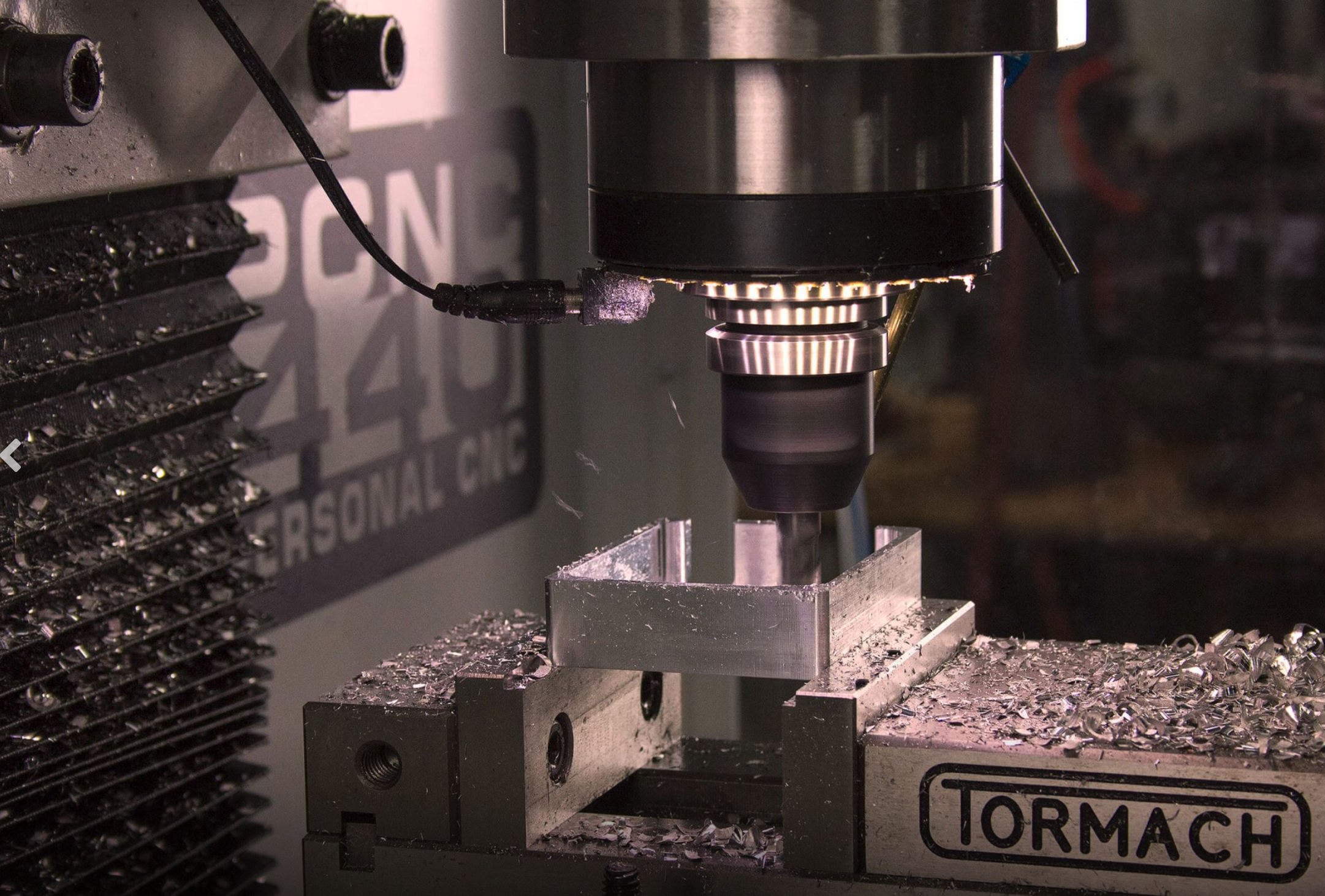

Tormach CNC Mill

This training course introduces the most sophisticated industrial machine in our workshops, the Tormach CNC Mill. This equipment is powered by digital CAD and CAM drawings that control the operations of the machine. For this reason, use of the CNC Mill requires familiarity with digital design software as well as the principles of manual milling and machining. This machine will allow you to automatically cut, shape, and drill metal and plastic workpieces into nearly any component you can design!

Successful completion of the training session will certify you on the Tormach CNC Mill.

Duration: 3 hours

Experience Level: Advanced

Pre-requisites: Metal Shop Fundamentals, Manual Metal Mill, CAD & CAM software familiarity

Price: $180

Please Note: If you cannot find a training session that fits your schedule, reach out to info@humanmade.org

We work hard to match members with the resources they need in a timely manner.